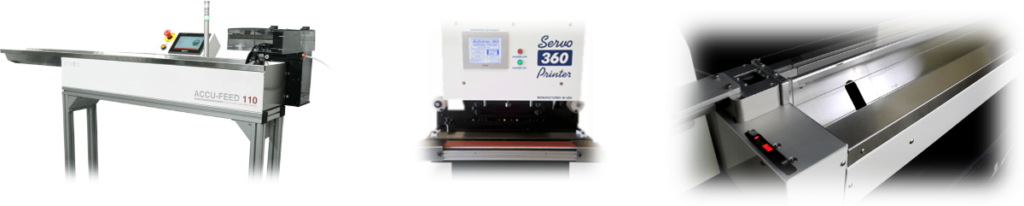

Catheter Printing Systems - Accu-Print Solutions

Description

SYNEO Accu-Print Catheter Printing Systems combine SYNEO’s best-in-class tubing materials handling and inspection techniques with pad and inkjet printing functions to meet precision printing specifications for unique medical devices. Accu-Print systems target pad printing and inkjet applications for a wide-range of device types including catheters, shafts, hypo tubes, trocars, and other devices that require critical 360° rotational markings.

SYNEO Accu-Print systems feature automation and efficiency enhancements such as:

- Rapid tooling changeovers for catheters with multiple-tubing dimensions

- Stick or spool automatic tubing feeding with integrated Cut-To-Length

- Automated vison inspection for print quality and position verification

- Integrated drying racks with programmable dry time

- Automatic pass/fail binning of finished parts

SYNEO works with customers all along the device life cycle from the low-volume prototype stages through ramp or mature production stages. Through internal technical resources and strategic partnerships, SYNEO combines catheter materials selection, manufacturing, and automation expertise to solve medical device application challenges.

SYNEO’s past Accu-Print automation applications include materials with low surface energy such as PEEK, PEBAX, Delrin and Silicone.

In addition to pad print and inkjet printing machine options, SYNEO’s equipment portfolio also features laser and mediablasting medical-device marking solutions.

Key Features

- Automated, precise picking and feeding of wire, metal and plastic tubing and rods

- Programmable print recipe functionality for location and tube sizing

- Multiple artworks per cliché with no requirement for manual print pad movement or part holding nest

- Smearing and smudging on catheter fixture is eliminated via ink tack dwell system

- Automated vision inspection system and pass-fail part diverting capabilities

- Wrenchless adjustments of print pads and fixtures

- Part Size Memory

- Automatic parameter calculations by French or diameter size

Materials

- Pebax, PVC, Pellethane, PEEK, Polyimide and others

- Straight lengths (stick form) of Polymer Tubing

- Straight lengths (stick form) Nitinol and stainless steel wire

Specifications

- 120-230 VAC, 50-60 HZ

- Ink Cup size up to 130mm

- Up to 80cm printing (standard dimension)